Sawdust Charcoal Indonesia

We produce sawdust charcoal briquettes made from 100% pure wood powder raw materials without any additives. The types of wood whose waste powder we use include merbau, bengkirai, keruing, ulin, mahogany, sonokeling, and various other hard forest woods and local wood mixtures.

The production process of sawdust briquette charcoal is significantly different from that of coconut shell briquettes. At Sawdust Crown Charcoal Indonesia, every stage is meticulously designed to ensure high-quality and consistent output.

1. Raw Material Mixing

The process begins by mixing wood sawdust from various types of wood, each combined based on a specific formulation and ratio. This initial mixing is done manually with the help of a wheel loader to ensure early homogenization.

2. Feeding into the Mixer

Once mixed, the sawdust is transferred into a Raw Material Sawdust Tank, then conveyed to the mixer machine. Here, the combination of wood types is blended more thoroughly — a critical step that contributes to 30% of the final product’s quality.

3. Drying with Rotary Dryer

The mixed sawdust is then channeled through ducting into a rotary dryer, with additional drying support from a jet blower cyclone. This ensures optimal moisture content before the material enters the high-pressure briquetting stage.

4. High Pressure Briquette Extrusion

Once properly dried, the material is fed into a High Pressure Briquette Extruder, which compresses the sawdust into solid briquettes. This stage plays a vital role in determining another 30% of the final product’s quality.

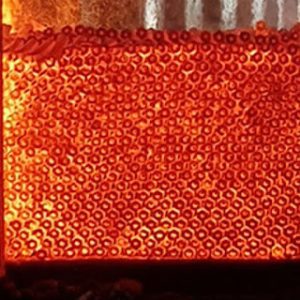

5. Carbonization in Kiln Stove

The freshly formed briquettes are transported via conveyor into the briquette tank, then loaded into the carbonization kiln stove. The carbonization process spans 15 days, consisting of: 🔥 7 days of burning ❄️ 7 days of cooling 📦 1 day of unloading This carbonization phase is the most critical, contributing to 40% of the final charcoal quality.

6. Sorting, Grading, and Packing

After carbonization, the briquettes are sorted by grade, then packed and made ready for delivery to our valued clients — both domestic and international.

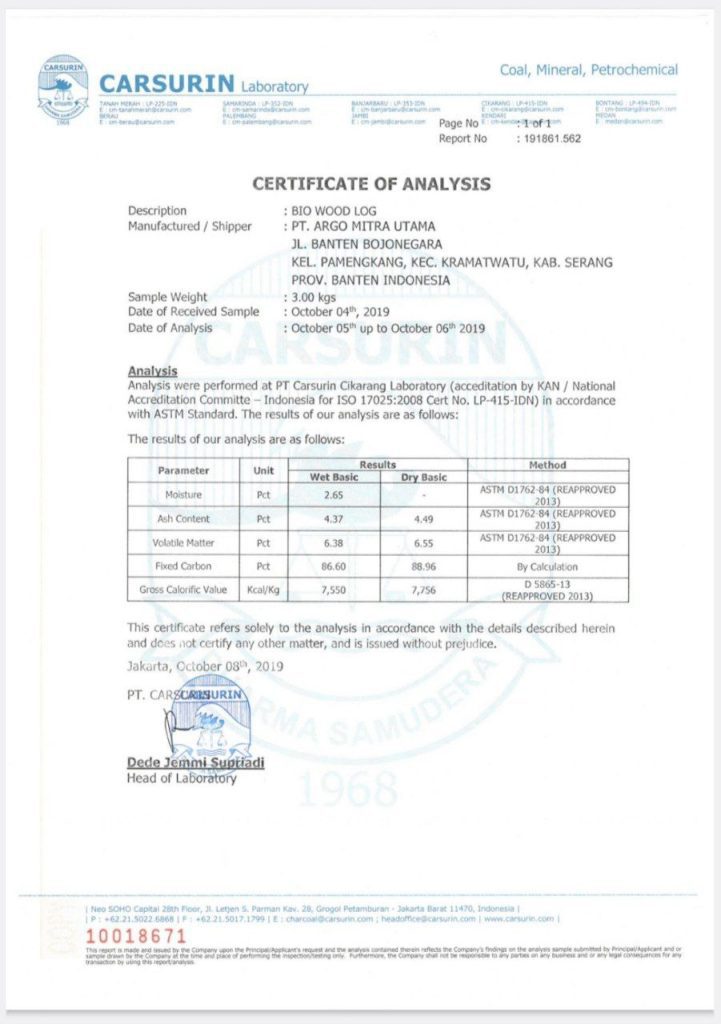

> 7700

KCAL CALORIFIC VALUE

> 88

PERCENT CARBON

6-7

HOURS BURNING TIME

0.10

ZERO HAZARD (CO)

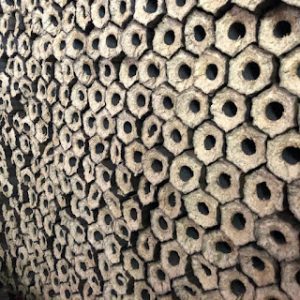

Grade A and B (Best for BBQ)

A and B Grade is suitable and highly recommended for best home barbecues and serious professional chefs. Length 10 cm up to 35 cm, Solid when packed, Burning time up to 6 hours.

Grade C and D (Suitable for Grill)

C and D Grade usualy use for daily grill and sometimes it can be used as more economical shisha charcoal also. Length 5 cm up to 10 cm, Bit Crack when packed, Burning time up to 4 hours.

Grade E and Below (Industry and Small Grill)

We also provide E Grade, Granule and Powder sizes for small grill uses and metal, ferrosilicon or briquette industry.

Shape

Stuffing & Shipment

Load

- 1x40FT FCL = 27 MT

- 10kg/box

Port of Origin

- Tj. Priok, Jakarta

Term & Condition

MOQ

-

The minimum Order Quantity

2 x 40FTHC

Payment Method

-

T/T Payment

50 % Deposit, 50% Balance payment settled upon loading, as evidenced by the copy of shipping documents which are confirmed. - L/C Payment

Gallery

Get in Touch

Crown Charcoal Indonesia provides consistent Premium Quality Products for various brands around the world, with performance, shape, and size that can be customized for every occasion. Set your own perfect quality standards! Get in Touch now!